Plasmatico

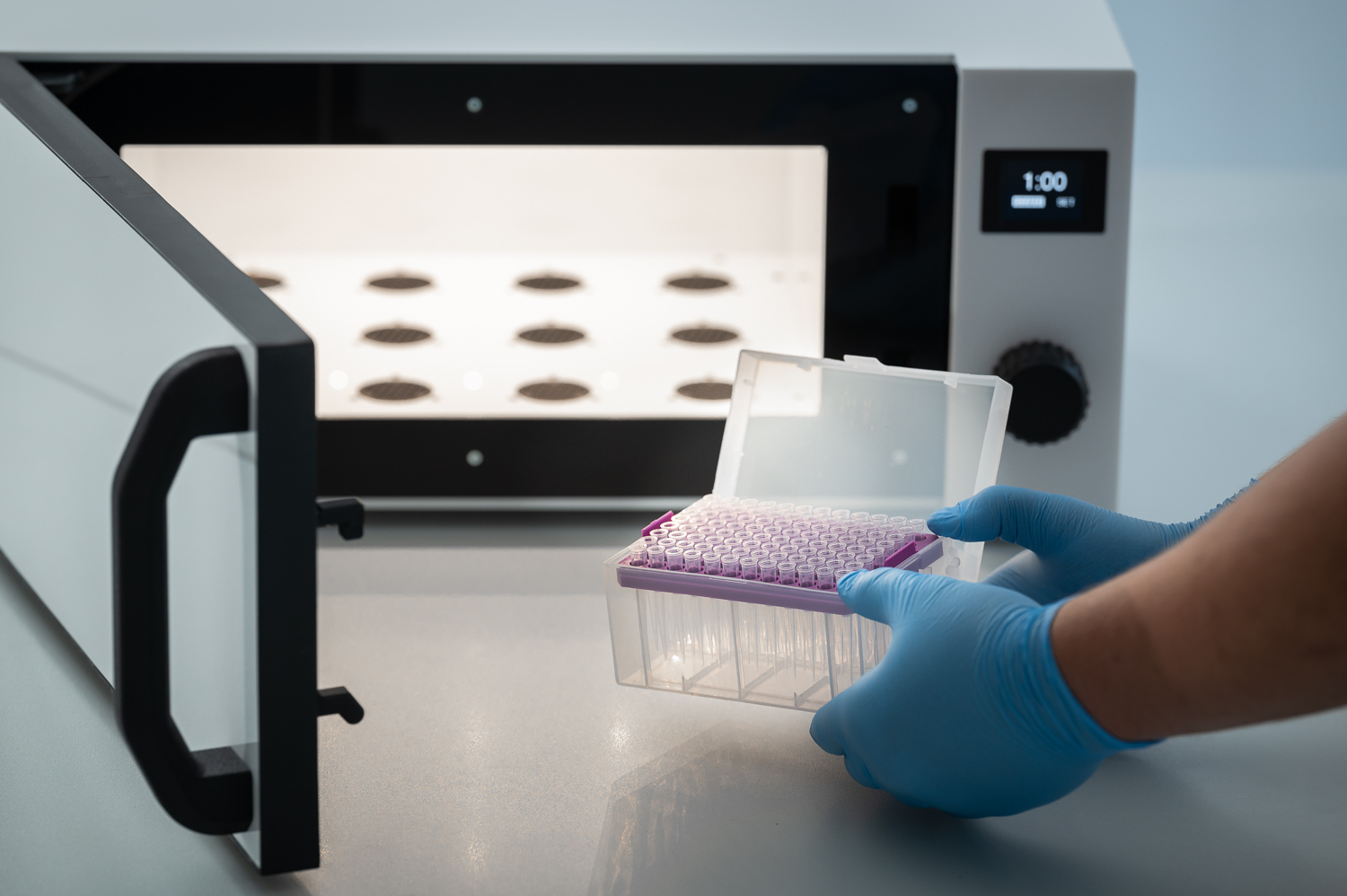

At Plasmatico, we are revolutionizing sterilization with cutting-edge non-thermal plasma (NTP) technology—delivering safe, efficient, and chemical-free decontamination solutions for biochemical laboratories, hospitals, veterinary clinics, and smaller healthcare facilities.

Medical & Healthcare

Laboratories

- Our journey began in 2020 with a mission to protect frontline workers during the global pandemic. What started as an urgent response to a crisis evolved into a groundbreaking innovation in sterilization. Partnering with leading research institutions, we developed Plasmatico, a next-generation sterilization system that eliminates pathogens without the need for harsh chemicals or extreme temperatures.

- Our technology is fast, cost-effective, and eco-friendly, ensuring the highest level of sterilization for sensitive materials such as medical devices, optical instruments, and electronics. Designed for versatility and reliability, Plasmatico is also ideal for field use in resource-limited environments, providing a robust sterilization solution in emergency situations or areas with restricted infrastructure.

- With CE certification completed and MDR certification in progress, Plasmatico is ready to set new standards in sterilization efficiency and sustainability.

Pioneering Plasma-Based Sterilization

The Beginning – Protecting Frontline Workers

In the midst of the COVID-19 pandemic, Plasmatico’s journey began as a non-commercial initiative, driven purely by the urgent need to prevent the infection of healthcare workers and first responders. At a time when protective equipment was critically scarce, we focused on developing and producing high-quality reusable masks (Covmask) to avert a collapse of the healthcare system. To make this possible, we launched a crowdfunding campaign, which became the second-largest in the country at the time, raising funds to ramp up production. We also forged strategic partnerships with Czech Technical University (CTU/ČVUT) and Czech Institute of Informatics and Robotics (CIIRC), whose expertise and resources helped us manufacture and distribute over 30,000 masks. These masks were first provided to hospitals and emergency responders, ensuring frontline workers had proper protection. As production scaled up, we extended distribution to senior care homes, where the need for protective equipment was equally critical.

From Emergency Response to Long-Term Innovation

During Covmask production, we faced a significant challenge related to sterilization. The particle filters we used in Covmask were highly effective but also expensive, making their single-use application financially unsustainable for many institutions. While the filtration efficiency was superior, hospitals and other organizations hesitated to use them due to cost concerns. Reusing the filters was a necessity, yet an effective and affordable sterilization method was lacking. As the pressure on the healthcare system eased and alternative protective equipment became widely available, we were at a crossroads—either end the project or adapt to a new challenge. We decided to continue our development by shifting focus to creating a dedicated decontamination device, capable of sterilizing particle filters and other sensitive materials effectively and affordably. This led to the birth of Plasmatico, a project aimed at utilizing non-thermal plasma (NTP) technology for safe, chemical-free, and scalable sterilization. In 2021, we formed a strategic partnership with the University of Chemistry and Technology in Prague (VŠCHT), which became a crucial research partner in the development of our device. Additionally, we established collaborations with several respected international institutions, further strengthening our research capabilities and bringing in top-tier expertise to accelerate the technology’s advancement.

Research, Testing, and Breakthroughs

Over the next two years, our team focused on refining the Plasmatico device, conducting rigorous laboratory tests to validate its effectiveness. We demonstrated the ability to eliminate bacteria, viruses, and other pathogens without using hazardous chemicals or high temperatures, making it a safer and more sustainable alternative to traditional sterilization methods. Key milestones included: • Successful testing against highly resistant bacteria (MRSA, Pseudomonas aeruginosa, E. coli) • Validation of virucidal effects against Influenza A (H1N1), SARS-CoV-2, Adenovirus, Rhinovirus, and Mpox • Optimization of sterilization efficiency, chamber design, and energy consumption During this time, we also built strong relationships with hospitals, laboratories, and industrial partners, ensuring that our solution met the practical needs of healthcare and research professionals.

Proven in Real-World Use

With our technology successfully validated in laboratory settings, 2024 marked the first real-world applications of Plasmatico. In response to the Mpox outbreak, our device was tested and proven effective against emerging viral threats, solidifying its role as a critical tool for infection control. At this stage, we also expanded our scalability efforts, ensuring that the technology could be adapted for different use cases, from small laboratory units to large-scale hospital deployments.

Certification & Market Readiness

In 2025, Plasmatico successfully obtained CE certification, making it officially ready for integration into hospitals, laboratories, and industrial environments across Europe. Additionally, the certification process under the Medical Device Regulation (MDR) is currently underway, ensuring compliance for broader medical applications. With full regulatory approval in progress, our device provides a cost-effective, scalable, and eco-friendly sterilization solution, meeting the growing demand for chemical-free and energy-efficient decontamination technologies. As we move forward, our mission remains the same: to revolutionize sterilization through cutting-edge plasma technology, ensuring safer, more sustainable, and highly effective decontamination solutions for the future.